A talk with Jiří Burda, CEO of NERKON s.r.o.

“Are there any dishwashers that do not use water?”

- Interviews

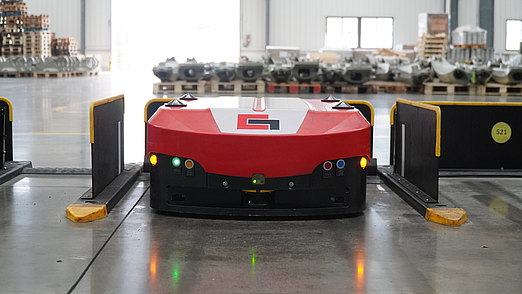

NERKON s.r.o. is a globally operating company for cleaning and degreasing equipment and provider of technological solutions for the logistics industry. Based in the Czech Republic they offer washing equipment for returnable packaging utilised in the food and non-food industry (e.g. the automotive sector). We took the opportunity and talked to their CEO, Jiří Burda, about their somewhat unique type of business, special solutions for the automotive industry and the countless varieties of crates and boxes that are used in warehouses around the world.

We offer specialized logistics solutions and warehousing facilities for the requirements of a range of industries.

Uniform standards in all of our logistics centers around the world ensure high quality and reliability. Benefit from our comprehensive network of warehouses in Europe, Asia and the USA.

Find out more