Transport by pendulum

- Facts

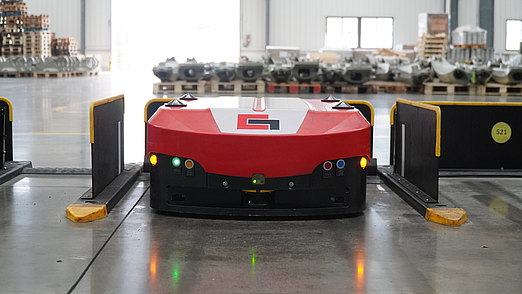

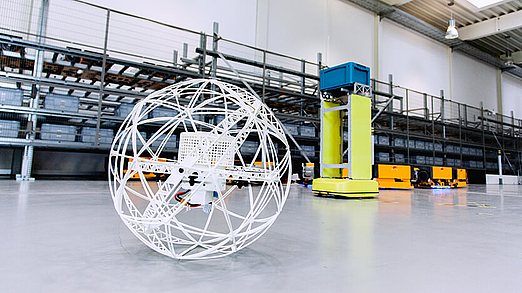

"Intelligent" robotic vehicles are a familiar concept in logistics. They move autonomously and are no longer bound to specific routes or predefined paths. The ability to “think in context” vastly simplifies logistical processes, resulting in ideally optimized warehouse operations. Some of these smart machines bustle about on four or more wheels, others fly around like drones through the building. But only the evoBOT “swings” on two wheels to always keep its balance – plus, it is no longer limited to warehouses but is also being put through its paces at the Munich Airport...

We offer specialized logistics solutions and warehousing facilities for the requirements of a range of industries.

Uniform standards in all of our logistics centers around the world ensure high quality and reliability. Benefit from our comprehensive network of warehouses in Europe, Asia and the USA.

Find out more