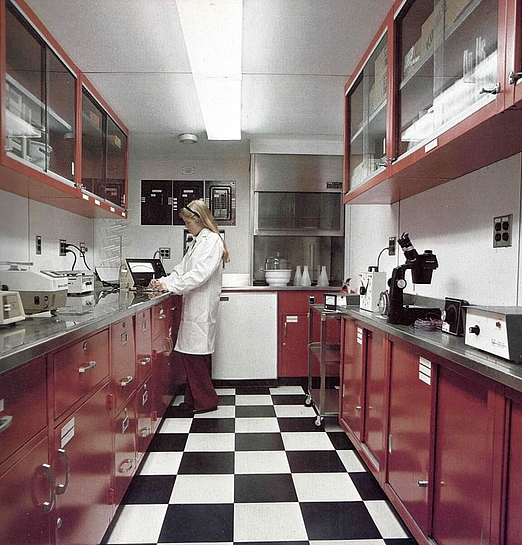

How va-Q-tec and cargo-partner secure the pharma cold chain

Cool Cooperation

- Facts

The transport of pharmaceutical products requires high logistical quality standards and often necessitates special technologies for temperature and humidity control. cargo-partner uses the innovative products of va-Q-tec to secure an unbroken cold chain. Nearly one year ago, the cooperation partners opened a TempChain Service Center near Vienna Airport where sophisticated cooling and packaging solutions are assembled for customers. We took the occasion to talk to va-Q-tec about challenges in cold chain logistics.