Pallets – the humble heroes of the transport industry

- Facts

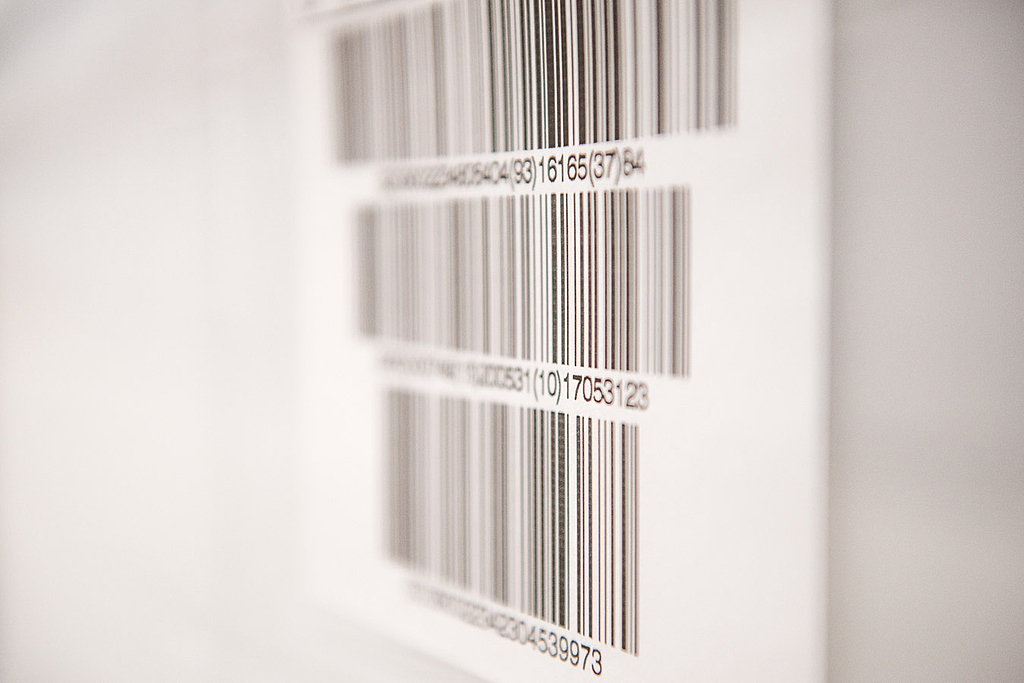

We all know them, even if we hardly give them a second glance. These simple platforms used to transport goods and stack them in warehouses are generally regarded as little more than a few pieces of wood nailed together. It may come as a surprise that pallets are actually worth a deeper look. And not only since they have lately become trendy upcycling objects in community spaces, living rooms and art galleries. What is the history of these humble “everyday heroes,” and what does the digital future have in store for pallets? We found out about modern pallets that are equipped with trackers, can send regular reports and are actually really “smart”!

We offer specialized logistics solutions and warehousing facilities for the requirements of a range of industries.

Uniform standards in all of our logistics centers around the world ensure high quality and reliability. Benefit from our comprehensive network of warehouses in Europe, Asia and the USA.

Find out more