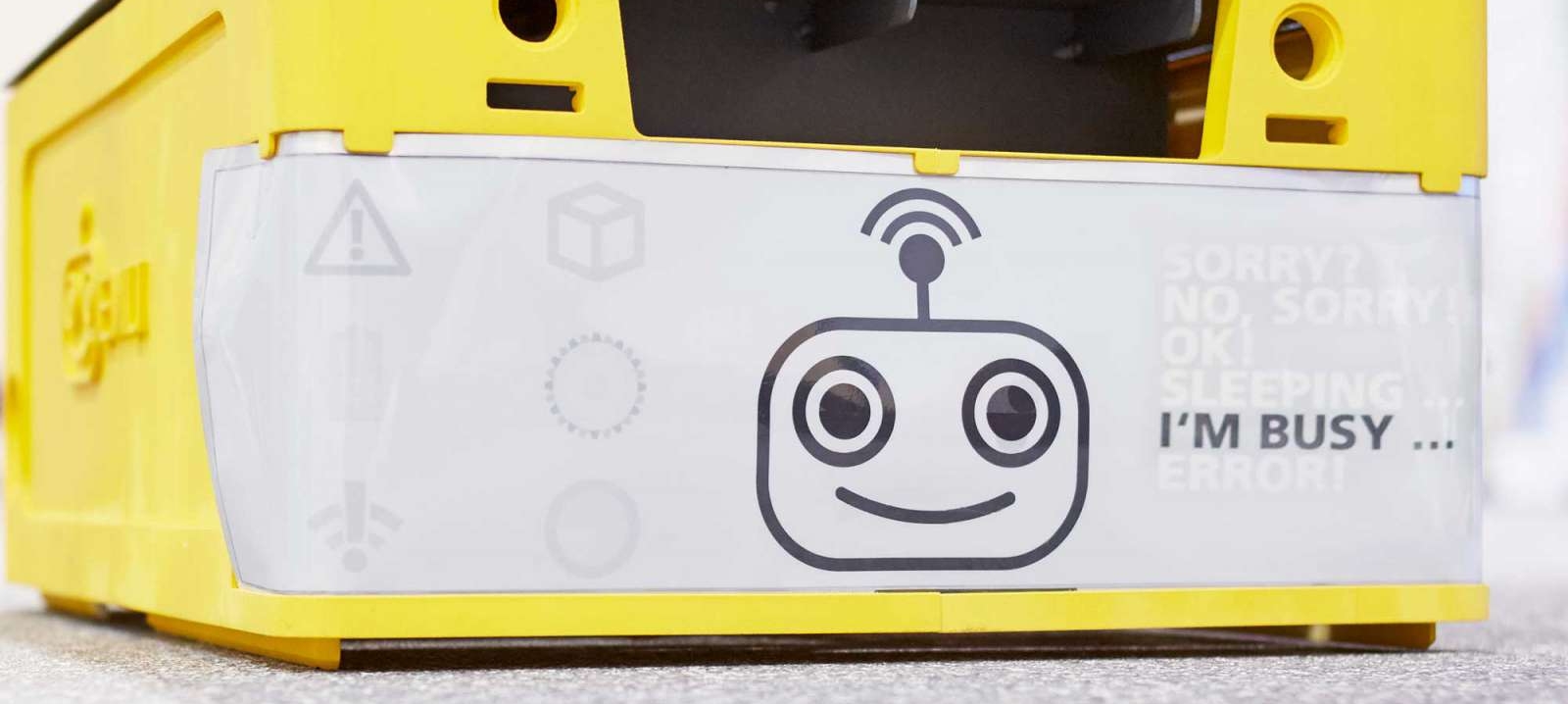

Meet Emili, Sawyer, ALIAS and SWIFTI

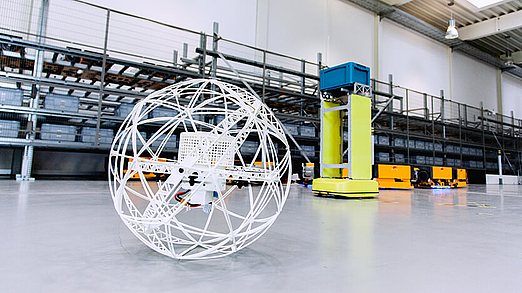

Cobots: Cooperation between humans and machines

- Facts

You may have already heard of “cobots” – collaborative robots – in warehouses or industrial production. But do you also know about the cobots working as gardeners, baristas or co-pilots? Since COVID-19, the possible uses and benefits of collaborative robots have grown even more: from cobots functioning as nurses to test stations managed by cobots.

We offer specialized logistics solutions and warehousing facilities for the requirements of a range of industries.

Uniform standards in all of our logistics centers around the world ensure high quality and reliability. Benefit from our comprehensive network of warehouses in Europe, Asia and the USA.

Find out more