Swarm intelligence revolutionizes logistics

Here comes the swarm!

- Insights

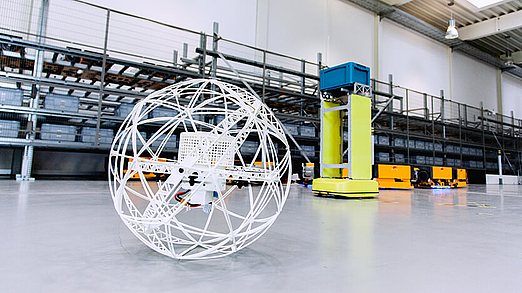

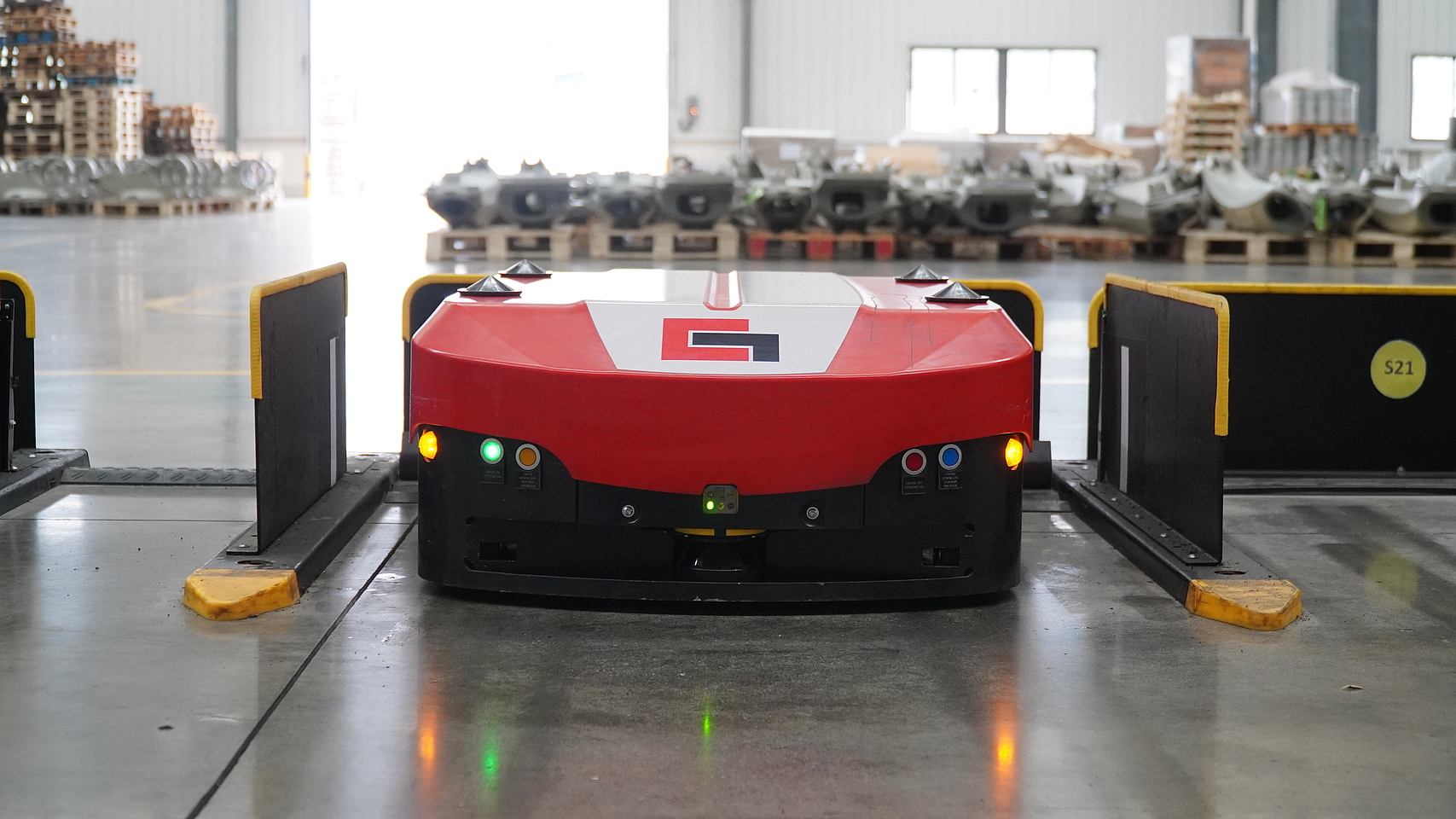

Collective work is the key to efficiency – that’s a well-known principle. Swarm logistics is considered a highly productive approach and is currently a big trend in the industry. Intelligent robot vehicles move autonomously and are no longer restricted to specific routes or paths. “Thinking along” and constant communication among the moving parts greatly simplifies logistical processes, achieving the best possible workflow in the warehouse. This concept is the future, so let’s take a closer look at the “swarm.”

We offer specialized logistics solutions and warehousing facilities for the requirements of a range of industries.

Uniform standards in all of our logistics centers around the world ensure high quality and reliability. Benefit from our comprehensive network of warehouses in Europe, Asia and the USA.

Find out more