Enhanced Visibility Reduces Higher Losses

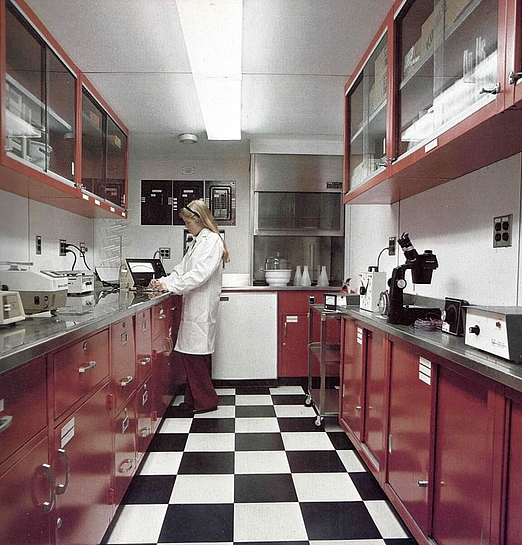

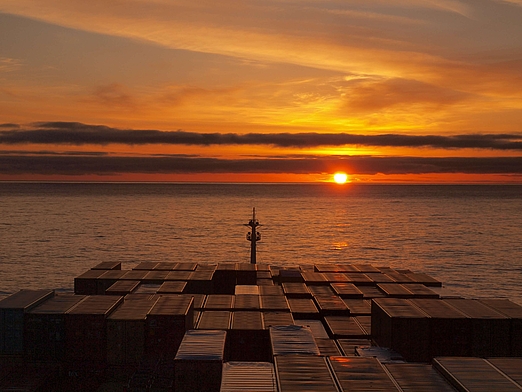

How trackers can help prevent food waste

- Facts

- Facts

A study by the FAO (Food and Agriculture Organization of the UN) estimates that around a third of all edible food is thrown away and calculates that these losses amount to approximately 1.3 billion tons of food waste per year. In less developed countries, agriculture and production account for higher losses. In industrialized countries, a lot of food is thrown away or (sometimes) not even harvested in the first place, because its shape and appearance do not correspond to the expected norm. This can be caused, among other factors, by problems in storage and transport. To prevent these problems from arising, tracking devices or ‘trackers’ are used.