The future of “wearables” in the warehouse

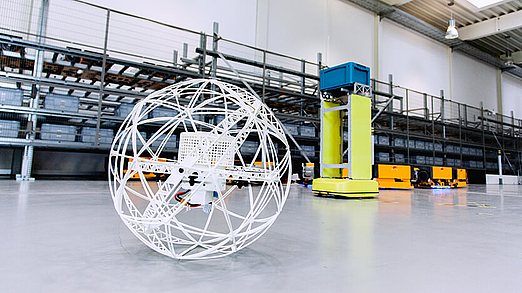

From learning exoskeletons to thought-controlled drones

- Insights

“Wearables” – small, internet-connected computers that are worn directly on the body – simplify everyday activities and leave users free to work with their hands. Devices such as ring scanners, smart gloves and augmented reality glasses are finding increasing use in the area of storage logistics. But did you know that wearables can learn from their wearers, move objects with the power of thought and also help stop the spread of COVID-19?

By outsourcing your logistics, you benefit from a competent partner who can optimize your processes and save you time and money.

We will be glad to advise you in detail about individual processes or create a comprehensive logistics concept for all your storage, inventory management and order handling.

Find out more