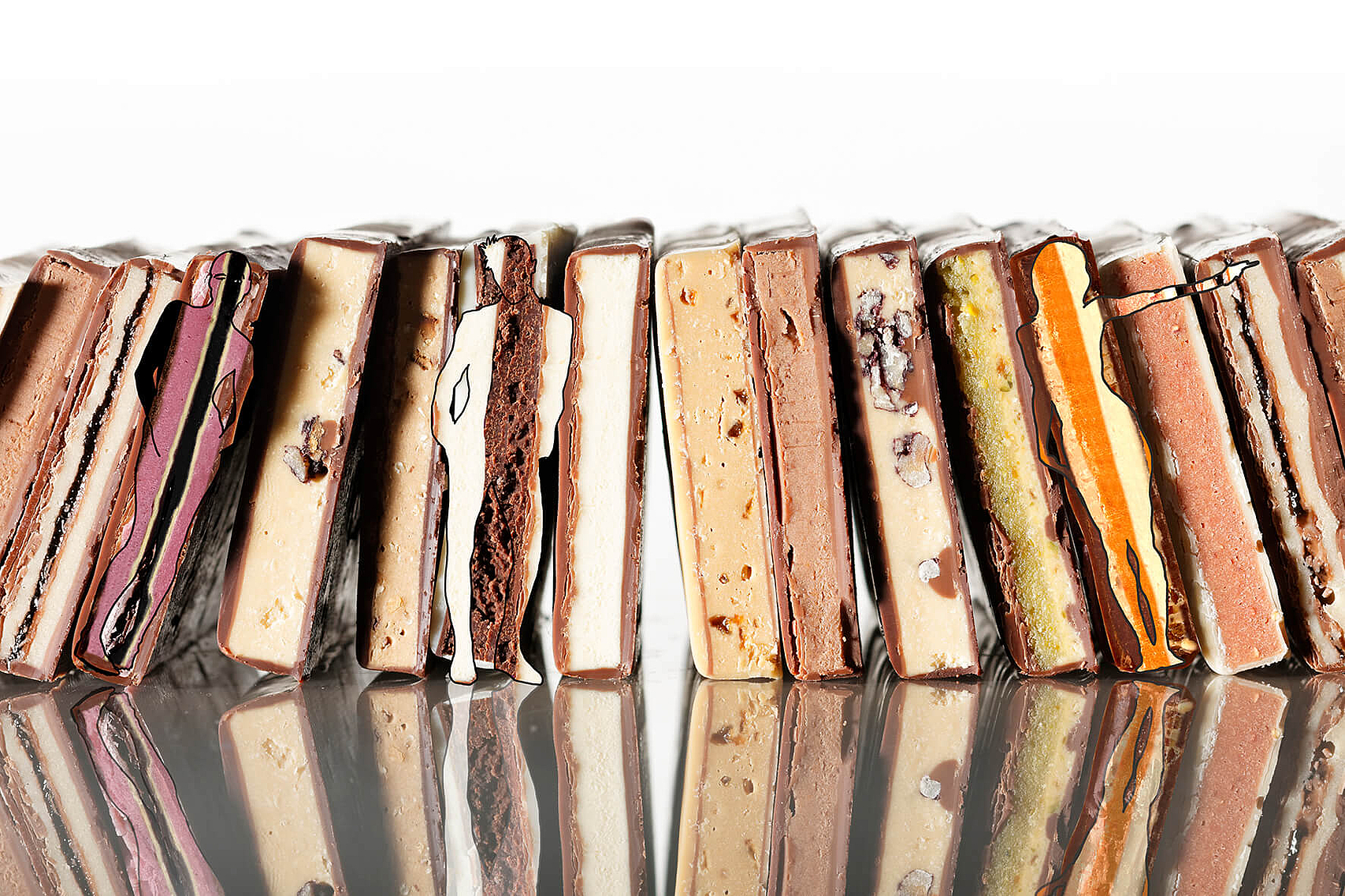

Melts in your mouth, not in the container

- Success Stories

- Interviews

The Austrian company Zotter is famous worldwide for its dedication to the art of crafting exquisite chocolate. Our interview explores how the one-of-a-kind flavors of these edible works of art are preserved during their transport by road, air and sea, how crystals can form in dried fruits and why bacon chocolate is especially popular in Asia.

“Storing cocoa beans in tropical climates poses a significant challenge because of the humidity. If mold grows on the cocoa beans, we cannot use them and the whole shipment is worthless.”

Julia Zotter on the importance of correct storage and handling of cocoa beans.

“In Europe, it always takes a little longer before consumers are ready to try the more unusual types of chocolate. But by now our customers here have also discovered that chocolates filled with sweet potato and passion fruit, or passion fruit and thyme, are quite delicious.”

Julia Zotter shares her observations on different chocolate preferences across continents.

Our rail service is 50% faster than sea cargo and 60% less expensive than air cargo, giving you the best of both worlds.

Rail transport is a fast, cost-effective and environment-friendly alternative to air and sea freight. Our specialized teams will create the optimal rail transport concept for any commodity.

Find out more