Order fulfillment 365 days a year

Efficient Spare Parts Logistics for ENGEL

- Insights

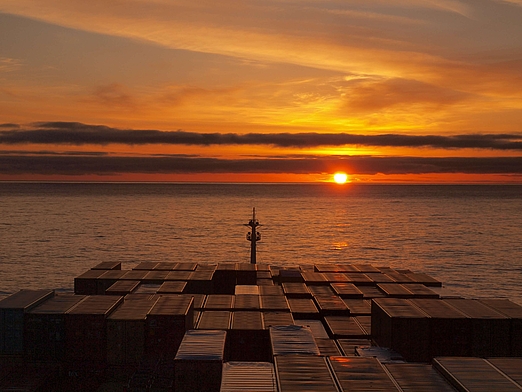

International machine manufacturer ENGEL has centralized its spare parts logistics with cargo-partner to optimize its worldwide spare parts supply. But parts are not just parts – some demand special handling under special conditions: cargo-partner’s iLogistics Center provides the ideal setting for such challenges.

We offer specialized logistics solutions and warehousing facilities for the requirements of a range of industries.

Uniform standards in all of our logistics centers around the world ensure high quality and reliability. Benefit from our comprehensive network of warehouses in Europe, Asia and the USA.

Find out more

By outsourcing your logistics, you benefit from a competent partner who can optimize your processes and save you time and money.

We will be glad to consult you in detail about individual processes or create a comprehensive logistics concept for all your storage, inventory management and order handling.

Find out more